Revolutionary Automated Pyrolysis System For Continuous Disposal of Agro waste

At JRKENERGY, we’ve engineered and patented a next-generation Fast Pyrolysis System For Continuous disposal of Agro waste.

What is Pyrolysis?

Pyrolysis of material takes place when it is heated to high temperatures in the absence of oxygen or in the presence of little oxygen. It is different from gasification, because in gasification, the oxygen percent is controlled to produce Syngas (H2 and CO). And both pyrolysis and gasification are different from combustion (which is the third thermo- chemical conversion process of organic material). In combustion, the organic material reacts with oxygen for complete transformation to CO2. The temperatures involved in Pyrolysis can range from 200-300 deg. Celsius on the lower side and to 800 deg. Celsius on the higher side.

Conventional Pyrolysis and

JRK's Fast Pyrolysis

Conventional Pyrolysis (also called Slow Pyrolysis) has been practiced for thousands of years to produce char. Waste material is slowly heated to 200–500°C, releasing vapors gradually. It yields about 30% liquid, 35% char and 35% gas (dry basis).

JRK’s Fast Pyrolysis, developed in the last 30 years, aims to maximize bio-oil production. The material, ground to 2–3 mm, is rapidly heated to 425–500°C and vapors are quickly cooled. This produces a dark brown bio-oil (≈1200 kg/m³, 4000–5000 kcal/kg, acidic, 12–15% water), stored in stainless steel and valuable as fuel or chemical feedstock.

Yields: 40% bio-oil, 30% bio-char, 20% syngas (dry basis) and 10% organic pesticides. No waste is generated—char and gases also have fuel value, with gases usable to heat the reactor.

How Our Process Works

Step 1: Preparation & Drying

- Agro waste (like bamboo, sugarcane bagasse, rice husk, cotton stalks) is dried to <10% moisture.

- Shredded & pulverized to <4 mm size for uniform heating.

Step 2: Pyrolysis Reactor

- Fed into a horizontal auger reactor, rapidly heated to 500-550°C.

- Absence of oxygen ensures thermal decomposition without combustion.

Step 3: Vapors & Gas Handling

- Vapors rise into condensers; rapidly cooled to yield bio-oil.

- Non-condensable gases (syngas) are routed to burners, partially powering the system.

Step 4: Activated Charcoal Collection

Char is pushed out, cooled and collected. Used across 75+ industries.

Step 5: Zero Waste Loop

- Syngas fuels dryers & pre-heaters, reducing external energy needs by ~99%.

- Result: highly energy-efficient & cost-saving operation.

Our Technology at a Glance

Parameter | JRK Fast Pyrolysis | Traditional Pyrolysis |

Bio-oil + Organic Pesticide Yields | 50% (40% + 10%) | ~30% |

Char Yield | 30% | ~35% |

Processing Time | Seconds | Hours |

Energy Efficiency | ~99% self-sustained | Low |

By-Product Utilization | 100% | Partial |

Emissions | Near-zero | High |

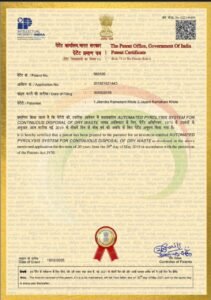

Patented & Proven

This is not just a lab concept.

Our technology is patented (published on the Govt. of India portal) developed over 10+ years with rigorous testing alongside NEERI, LIT Nagpur and Maharashtra Bamboo Development Board.

Our Nagpur Bamboo Waste Pilot Project validated:

- Conversion of bamboo agro waste into high-value bio oil, LDO, syngas & activated charcoal.

- Commended by ministers including Shri Nitin Gadkari & Shri Dharmendra Pradhan.

How Our Process Works

Multi-Product Revenue Streams

Bio-oil, LDO, pesticides, activated charcoal, syngas.

Decentralized

Can be set up from 10 TPD to 40 TPD, easily scalable.

Rural Employment

Each unit employs ~60+ direct staff, plus indirect jobs.

Low Processing Cost

₹12-15/kg of agro waste, with product sale recoveries of ₹40-50/kg+.

Rapid ROI

Most units achieve full payback in ~2 years.

Zero Waste, Maximum Impact

Because our system:

- Burns syngas to power itself,

- Sells bio-oil & LDO as industrial fuel,

- Markets activated charcoal at ₹75+/kg and above,

- Distributes organic pesticides back to farms,

it delivers a 100% utilization of input, making it one of the most sustainable waste to energy solutions in India.

Why This Matters

650 million tonnes of agro waste produced yearly and most of it burned on fields, causing pollution & health issues.

With our technology, this waste becomes fuel, jobs and income, supporting India’s goals under Clean Energy & Rural Development Missions.

Interested in Technology Partnerships or Pilots?

Whether you’re an investor, CSR head, FPO, or government agency, our patented fast pyrolysis (Continuous) systems are ready to be deployed across India.